Laser Cutting Machines: The Next-gen Sheet Metal Processing Products From Tube Form Solutions

Walking down the path of innovation, we at Tube Forms Solution introduce you to a world of advanced Laser Cutting Machinery from leading brands in the world. When it comes to sheet metal fabrication, efficiency and accuracy is the most important. However, using conventional techniques can never help manufacturers achieve the desired results. That’s why we have included an advanced laser cutting machine in our product range, the first of its kind to ensure our clients can easily steer around the bottlenecks and enhance operational efficiency with ease.

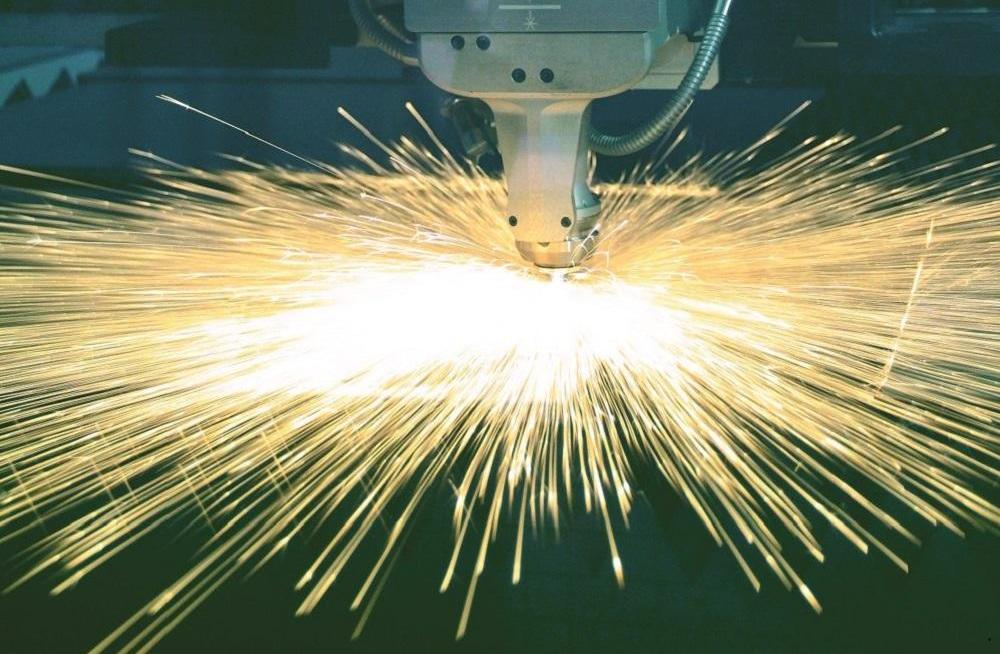

Laser Cutting Machines: A State-of-the-art Technology

Laser technology has paved its way in several industries, from healthcare, and manufacturing to aviation and so on. Its introduction to the manufacturing and fabrication industry has opened a myriad of opportunities for companies, allowing them to switch to this latest and innovative technology from the obsolete ones. Laser can be regarded as a strong beam of light having high intensity so that it can generate a huge amount of heat to cut through different metals and non-metals.

In a typical laser-cutting machine, optical fibers are often used to generate the laser beam, which is then directed over the workpiece via a robotic arm. Once the high-intensity beam is made incident on the material sheet, it melts the material and creates a keyhole. This acts as the origin of reference, allowing the operator to move the laser arm in the pre-determined direction to cut through the material.

Benefits of Using Laser Cutting Machines Over Other Cutting Methodologies

High Cutting Speed

A major advantage of using the laser cutting machine is its ability to make cuts at lightning speed. The machine can handle multiple sheets and create cuts in a single cycle when compared to conventional water or plasma cutters. Thus, the production cycle timeline can be reduced and the overall number of units generated will be quite high.

Precision & Accuracy

Laser cutters provide exceptional accuracy and precision for intricate cuts on sheet metals, preventing production delays and defects. The laser beam's width can be adjusted via integrated software, and automated routines with CAD/CAM guidance ensure swift, precise cuts.

Reduced Material Damage

The laser cutter can significantly reduce material damage and wastage. The laser beam doesn’t have any direct contact with the workpiece, owing to which no friction is generated. The surface wear and tear can be reduced significantly and the edges around the cuts will be cleaner and more uniform.

Optimal Production Quality

Whether needs precision in the cuts or contactless operation, the quality of the sheet metals isn’t compromised by any means with Laser Cutting. As a result, manufacturers can easily maintain the production cycle and improve the overall deliverables for better customer satisfaction.

Versatility

Laser cutters can cut various materials by adjusting frequency and wavelength. For example, an optical fiber laser cutter can accurately cut both metals and nonmetals. The same machine can also cut metal sheets of different thicknesses by adjusting the beam intensity and wavelength.

Safety

Using laser cutting can help to enhance safety. It reduces the risk of accidents and injuries compared to traditional cutting methods. Additionally, the enclosed design of many laser cutters protects operators from direct exposure to the laser beam.

Buy Laser Cutting Machines From Top Brands With Tube Form Solution

Why Choose Tube Forms Solution For Laser Cutting Services?

Value For Money

At Tube Forms Solution, we acknowledge the fact that the investment needed to acquire a laser cutter is significantly high. Hence, we maintain a variable pricing model for our products in adherence to the market rates.

Multitudinous Options

We have stocked different types of laser cutters, including 2D, 3D, and CNC-based machinery units. Therefore, you can choose the best one that can meet the specific technical and business requirements.

Proven Guarantee

The laser cutting machine undergoes a thorough testing schedule before being launched at the market for final sale. That’s why we are certain of their operational efficiency and work quality when exposed to real-time projects.

Invest in What Matters the Most With Tube Form Solutions

If you want to cut through the market bottlenecks and bring a revolution in sheet metal fabrication, do not wait any longer and get in touch with our consultants. We will walk you through the features and specifications of latest laser cutting machine so that you can make the right call and invest in the best product.

Lease A New Laser Cutting Machine

Through our financing partners, you’ll find financial programs, leasing, and loan services at very competitive rates. No Financials or Tax Returns are required* and credit decisions are usually made within 24 hours.