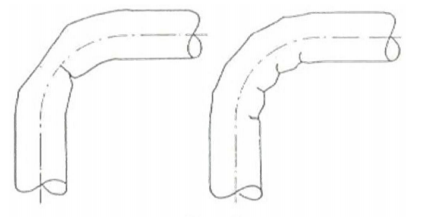

However, sometimes issues will still crop up when bending. One common issue is a kinked or buckled bend.

What causes kinked or buckled bends?

One of the main reasons a tube may be kinking or buckling during the bend has to do with the hardness of the material. When a material is too hard, it may not compress on the inside radius of the bend. This lack of compression forces the material to push toward the tube's center line.

How do you solve this issue?

Like many common tube bending issues, kinked or buckled bends can be prevented by properly setting up your tooling. The importance of a proper tooling setup cannot be overstated.

However, when the tube buckles and is still within the wall factor and the diameter of the bend, a plug mandrel is often the best solution.

Why use a plug mandrel bender?

The purpose of a plug mandrel is to prevent the tube from flattening while bending without wrinkles or kinks. Plug mandrels are an inexpensive, easy-to-maintain solution that causes little drag.

A mandrel is a good solution for kinks or buckling because it supports the material through the bend. So even hard materials can be bent with minimal fuss.

Learn More

Click here or follow the link below to download a free introduction to tube bending to learn more, or contact us at any time with any questions or comments you may have.